| Product Name |

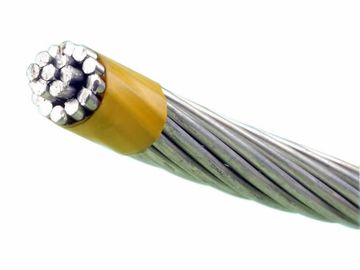

All Aluminium Conductor (AAC) |

| Material |

Aluminium |

| Color |

Silver |

| Standard |

GB/T 1179-2008(equivalent to IEC 61089), ASTM, CSA, DIN |

| Application |

Overhead, construction, power station |

| Jacket |

Bare |

| Model |

Huanghe-AAC |

| Origin |

China |

1. Application

AAC conductor is also known as aluminium stranded conductor. It is manufactured from electrolytic ally refined aluminium, witha minimum purity of 99.7%. AAC is used mainly in urban areas where the spacing is short and the supports are close. All aluminium conductors are made up of one or more strands of aluminium wire depending on the end usage. AAC is also used extensively in coastal regions because it has a high degree of corrosion resistance.

2. Service Performance

2.1. The permissible long-time operating temperature for aerial conductor is 70℃.

2.2. Under the circumstance that rare climate is occuring and ice coverage rate low in heavy ice area,the biggest stress of cable at the lowest point of the sag should not exceed 60% of the short-time destructive power.

2.3. When connecting conductors, the conductor beside the connecting tube cant be prominent. Otherwise the force on the operating conductors will be unbalanced. After connectors are install, the connecting tube should be painted by moisture-proof varnish in order to protect it from corrosion.

2.4. Under installaion, the arc downing stress of all the conductors should be the same. With in the permissible distance of crossing buildings or dropping to the ground, the stress can be 10-15% higher than regular stress.

3. Product Performance

3.1. The electrical performance of AAC is indicated in DCΩ/km (20℃). The resistivity of the hard aluminum wire for stranded wires is not greater than 28.264 nΩ. m of international standard value.

3.2. The rated tensile strengh of AAC is denoted with sum of all aluminum conductorstensile strength and steels tensile strength.

a. The tensile strength of all aluminum conductors is denoted with the result of all cross sections of aluminum conductors multiplied by min. tensile strength of corresponding size specified in the standard for aluminum wire.

b. The tensile strength of all steel wire is denoted with the result of all cross sections of steel wires multiplied by the stress at 1% elongation of corresponding size specified in the standard for steel wire.

4. Material Standard

4.1. The zinc coated steel wire used for AAC conforms to IEC 61089.

4.2. The hard aluminum conductor used for AAC conforms to the standard GB/T 1179-2008 (equivalent to IEC 61089).

4.3. Production can be arranged according to customers requirements for material standard etc. (such as ASTM B232, IEC61089, BS215, DIN48204, BS EN50182 etc.)

AAC Technical Characteristics Based on Standard DIN 48201 / DIN EN50182

| Code number |

Area |

Number of wires |

Wire diameter |

Conductor diameter |

Linear mass |

Rated strength |

D.C. resistance at 20oC |

| mm2 |

NO. |

mm |

mm |

kg/km |

kN |

Ω/km |

|

| 16 |

15.9 |

7 |

1.7 |

5.1 |

43.4 |

3.02 |

1.7986 |

| 25 |

24.2 |

7 |

2.1 |

6.3 |

66.3 |

4.36 |

1.1787 |

| 35 |

34.4 |

7 |

2.5 |

7.5 |

93.9 |

6.01 |

0.8317 |

| 50 |

49.5 |

7 |

3 |

9 |

135.2 |

8.41 |

0.5776 |

| 50 |

48.3 |

19 |

1.8 |

9 |

132.9 |

8.94 |

0.5944 |

| 70 |

65.8 |

19 |

2.1 |

10.5 |

180.9 |

11.85 |

0.4367 |

| 95 |

93.3 |

19 |

2.5 |

12.5 |

256.3 |

16.32 |

0.3081 |

| 120 |

117 |

19 |

2.8 |

14 |

321.5 |

19.89 |

0.2456 |

| 150 |

147.1 |

37 |

2.25 |

15.8 |

405.7 |

26.48 |

0.196 |

| 185 |

181.6 |

37 |

2.5 |

17.5 |

500.9 |

31.78 |

0.1588 |

| 240 |

242.5 |

61 |

2.25 |

20.3 |

671.1 |

43.66 |

0.1193 |

| 300 |

299.4 |

61 |

2.5 |

22.5 |

828.5 |

52.4 |

0.0966 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!